The 8 Disciples (8D) of Problem Solving Process is one of the most effective problem solving processes that can be successfully applied in many different types of industries and organizations to identify and eliminate the underlying symptoms/root causes of a problem.

Serious consequences occur when an elaborate problem solving procedure like 8D is not implemented and a quick fix is accepted as final, permanent solution. I often observed that excessive reliance on containment actions like Operator Error and Work instruction training will create a repeating issue cycle unless the underlying symptoms are not addressed.

In this blog, I’ll briefly discuss how i always prepared myself for 8D problem investigation and pursued permanent solutions for manufacturing complaints.

The first stage of 8D is establishing a small group of people with process and product knowledge. This typically done by either Quality Engineer or Quality Manager who acts as Team Leader and Problem Solving Champion.

Key points to remember during this stage include :

- Selecting right people

- Size of the team

- Effective communication about the problem

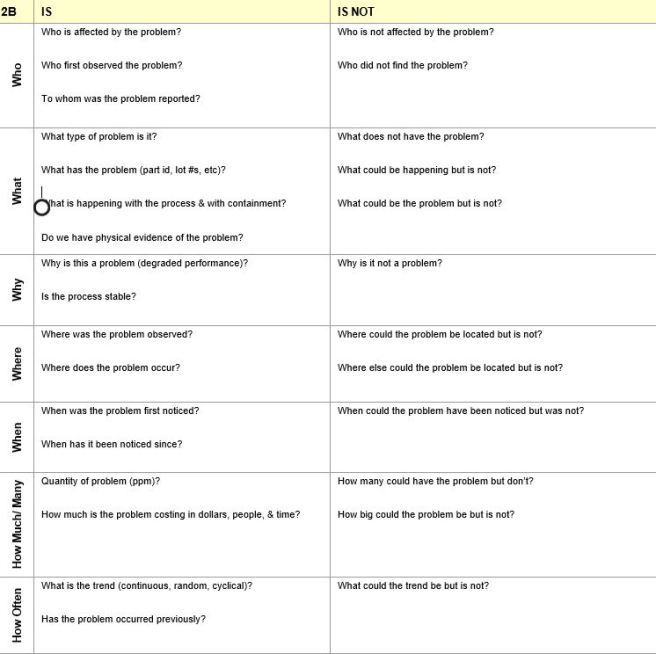

A good problem should have great problem statement. While describing the problem, it is important to include as much information as possible. These reports will be a reference point when a similar issue occurs in the future. All my 8D reports include detailed information about the customer problem. This is to make sure non-technical readers understand the report first time and to leave tracks so that in the future another reader will be able to extract all original data. (I strongly recommend using IS-IS not approach to gather critical information before writing the problem statement)

Once the problem statement is established, A typical 8D process requires interim containment actions. However, Keeping in view of customer’s interests, I always directed containment actions even before initiating 8D’s. Few weeks ago, I was notified by a customer that they have received defective material. I initiated containment actions immediately after the notification which helped avoid shipment of more defective material that is on the stock. It is also important to make sure that this voice of the customer is reaching out to all employees through internal quality alerts, quality notices etc. as soon as an issue is brought to attention by customer. A more robust containment actions can include : Training the affected department on workmanship standards, A temporary increase in inspection level.

Once the containment actions are in place, its now time to investigate the problem. This is a time consuming process and often involves detailed study of the manufacturing processes. As 8D Team Leader, I have always encouraged the cross-functional teams to start off with brainstorming all possible causes that led to process failure. This is facilitated using Ishikawa/Fishbone diagram. This approach calls for listing all possible causes of failures from different standpoints (Man, Machine, Material, Measurement, Method, Mother Nature). After listing down all possible causes on Fishbone diagram, the team shall select what causes are relevant to the issue and what can be excluded for further analysis. Prioritize the relevant causes by most probable, probable, least probable cases. Once the team agrees with most probable causes, I would recommend asking “Why?” question five times based on both manufacturing processes and quality processes in order to get to the underlying symptom.

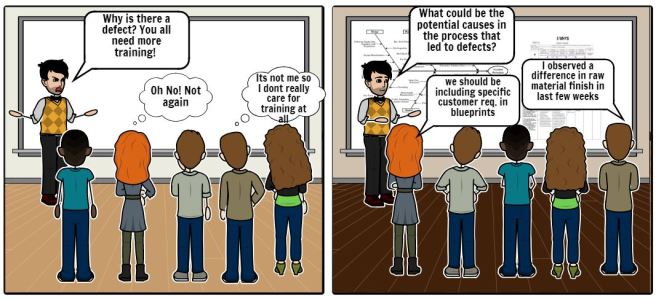

I usually avoid brainstorming on “Manpower/People failure” during team sessions and assess this factor during my own investigation. I have been to several problem solving sessions in the past where the topic of discussion centered only on operator’s fault. This strategy neither fixed the problem nor was able to stop complaint cycle. As a team leader and facilitator, one must make sure that the discussion is always centered around improving the existing process and how the leader can make operator job easier by fixing the process. I remember a case study at a company where a bundle of stainless steel material supposed to run through a critical operation but it didn’t and proceeded to final manufacturing operation and was able to reach customer site. Thanks to SAP ERP software, It is possible to track entire order history beginning from raw material purchase to customer complaint complaint notification including Workstation Manufacturing Order, operator confirmations at each workstation and shipping date.

But does tracking down the operator who is at fault and confronting him about the magnitude of the problem solves the issue? Absolutely not! We need to understand deeper issues like: Why did the manufacturing process not prevent the incident? Why did the quality process not detect the incident? Fixing the potential loopholes that come out of these questions would stop the complaint cycle and will bring a sense of confidence to quality personnel about the process.

For Example : After listing down all possible causes from fishbone, a problem solving team agreed that the seal failure on riveting machine’s hydraulic ram could be the most probable cause for inconsistent rivet strengths on clamps. We will now investigate this issue in two paths :

– Path A –

1st Why Question : Why clamps have inconsistent rivet strengths?

Answer : Load cell attached to riveting machine indicates that the pressure with which the machine hits the rivet on the clamp varies with every hit.

2nd Why Question : Why does the machine load varies with every hit?

Answer : There’s a trickle of hydraulic fluid down the side of the ram during operation which may indicate a possible seal failure

3rd Why Question : Why did the manufacturing process not prevent the seal failure?

Answer : The workstation periodic preventive maintenance check did not include seal condition.

Continue till 5th Why to finalize the problem root cause pertaining to manufacturing process.

– Path B –

1st Why Question : Why did the quality process not detect inconsistent rivet strengths?

Answer : Workmanship standard did not include torque requirement as specified by customer

Continue till 5th Why to finalize to identify gaps in quality assurance/quality control process.

Note : After writing answers, they must pass these tests :

- Do I have proof that this statement is true? Is it tangible or measurable?

- Do I have a proof that this actually contributed to the problem?

- Does the path make sense when I read in reverse?

Once root causes are identified, assign responsibility to the individuals and collaborate with them to take measures for corrective actions. A preventive action would include updating inspection plans, control plans, work instructions, process flow charts, PFMEA, lessons learned log on concerned processes.

The final step in 8D is recognizing and congratulating the team. If recognition is not given, team members are less willing to participate and are likely to become discouraged. Recognition and feedback is the most effective method available to shape behavior. It creates a good environment for future interaction, reinforces the strength’s of team work, improves self-esteem and facilitates personal growth.

Have you been a team leader for 8D’s? What was the most challenging aspect for you in this problem solving procedure? What do you think are some of the best practices everyone should adopt for 8D’s? Let me know in the comment section below! In my next blog, I’ll discuss my experience in leading quality function activities in new product launch projects.